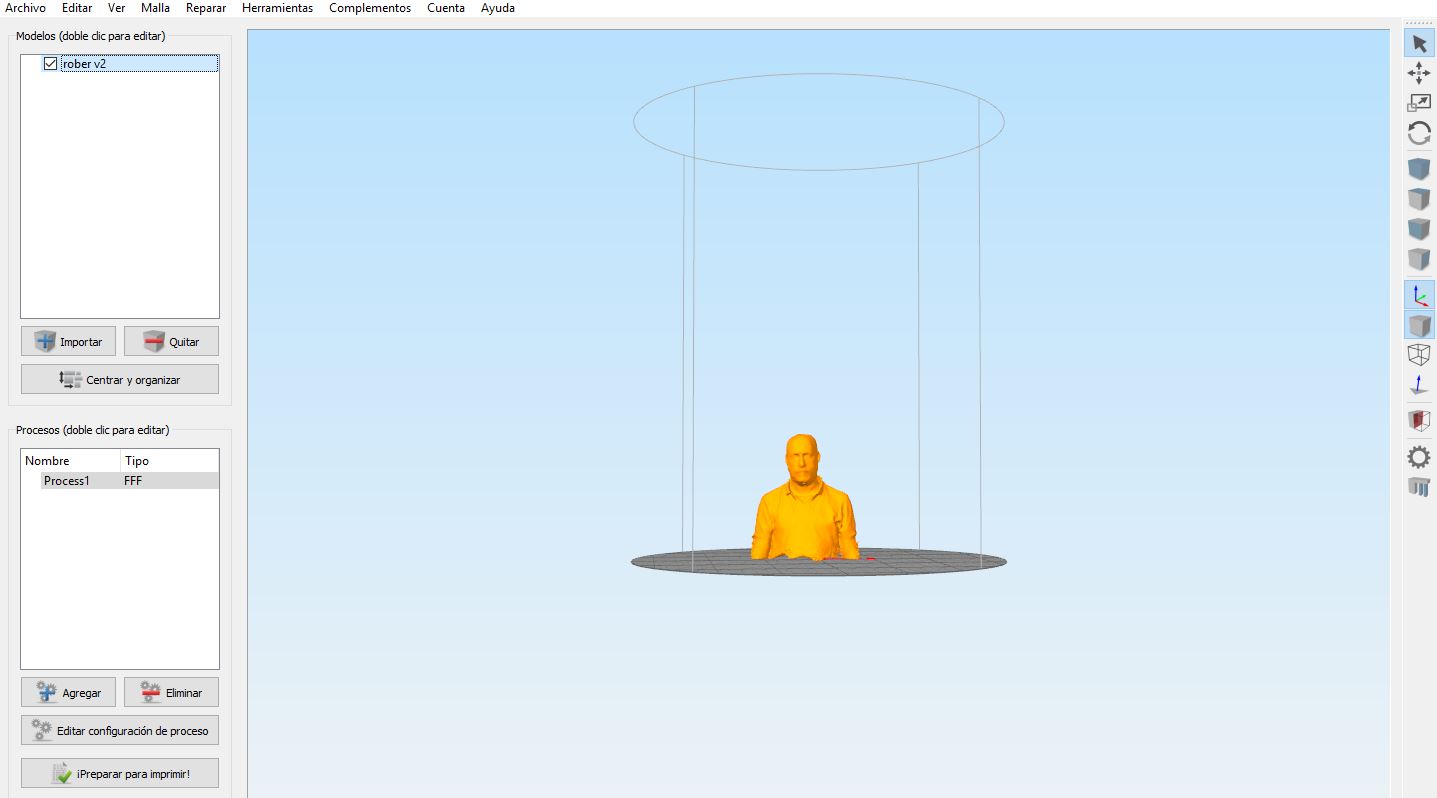

It has information regarding the surface geometry of the model. It stands for “ STero Lithography,” sometimes also called - Standard Triangle Language/Standard Tessellation Language. It stores the visual image of the 3D model. The main function of the slicing software is to work with the STL format file. Buildbee’s user interface (Web-based slicer software) It enables the user to move, scale, rotate, and change the settings for the 3D model. As you can see in the picture below, the graphic user interface of a free web-based software named Buildbee. It has all the tools that help the user interact with the 3D model.

Let us look at the components of the Slicer software. The back-end components contain algorithms or instructions for the code execution. This is where the user visualizes the CAD, as well as the gCode and tool path. The front-end consists of the parts that the user directly interacts with. Like every software, we can divide it into two components - front-end & backend, OR - GUI and Logic. It is important to understand how data flows in the 3D printing process. In the next few sections, we will delve into some of these Slicer settings that will directly impact the 3D print qualityof the models.

“3D printing, also called additive manufacturing, turns digital files into physical objects by building them up layer-by-layer. That is how all machines work and 3D printing is no different. Machines also use tools at their disposal to translate a set of instructions into formidable actions. Like humans, machines have methods of processing information. Humans are gifted with senses that help make decisions and perform activities.

0 kommentar(er)

0 kommentar(er)